This page may contain affiliate links. As an Amazon Associate I earn from qualifying purchases.

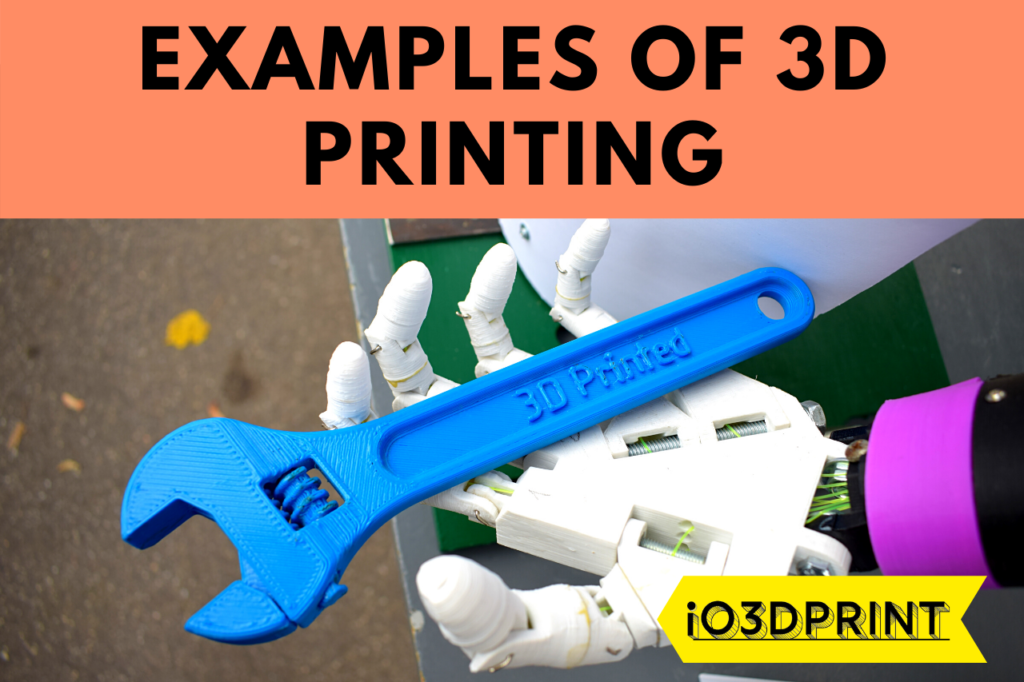

Examples of 3D Printing

Introduction

The invention of 3D printing has undoubtedly been a breakthrough that has revolutionized manufacturing. With continued innovation, both home users like you and I, as well as big manufacturers, can now easily access and use 3D printers.

This is possible because 3D printing has become not only increasingly affordable but also an excellent alternative to traditional manufacturing methods that guarantee quick product creation.

In this article, I will take you through some of the most popular examples of 3D printed objects, either for your home or business. Then, you will be able to appreciate how 3D printing technology has improved all of our lives.

Construction of Structures and Buildings

Numerous companies across the globe are using 3D printing to make 3D printed structures and buildings. The materials used in these processes include plasters, recycled materials, concrete, as well as glass and carbon fibers for strength.

3D printing has been quickly embraced as the total construction cost is often very low, and customization is quick and easy, hence making it an appealing option.

Various organizations and companies have realized the feasibility of 3D printing and have thus started using it to undertake construction projects. It should not be a surprise if later in the future this technology is seen as a cheaper option in comparison to the traditional methods which are currently preferred.

Therefore, 3D printing technology is undoubtedly a dynamic, extensive, and exciting technology that holds a lot of promise for the construction field.

Manufacture of Vehicles

The automotive industry has also embraced this innovative technology. Whereas this might not have been imagined by many, 3D printing is a remarkable car manufacture option that many car manufacturers are turning to.

3D printing is often seen as a process for making a small number of components, but large auto companies are finding ways to make it work for large production runs that suit their manufacturing timescales.

The first and most important reason for using 3D printed parts is the ability to reduce weight. This is because 3D printed parts are usually designed to be extremely lightweight and simultaneously very robust because they can have highly organic shapes with hollowed areas that would be impossible to manufacture from any other method.

But this depends on the material used. Manufacturers also considered a strength, with 3D printed printing making it easier for support to be created within the parts or during the customization of parts by controlling the printing methods.

Moreover, price is another reason why manufacturers are gradually starting to shift to 3D printing. The reason for this is if this technology is implemented correctly and the right parts are used, the total manufacturing cost will be much lower compared to the traditional methods of manufacturing. This is possible since it is easier to develop the custom and complex parts, thereby saving not only money but also time.

It will still take a while for a fully 3D printed car to be accepted on the road by law since they need to first go through several safety measures. However, with the rapid advancements in this technology, this thought is not far-fetched.

Musical instruments

3D printing technology has been used to make several musical instruments, including banjos, flutes, and Stradivarius violin. Additionally, 3D printers have been used to create some musical instrument parts, for instance, mouthpieces. At Lund University, Sweden, the first live concert across the globe using 3D printed musical instruments, that is, two guitars, a keyboard, and the drum were performed.

Firearms

The use of 3D printing technology to print guns is a very controversial issue, especially after the first-ever 3D printed gun was shot in the United States. Almost all the parts of this 3D printed gun were made from ABS plastic, and the only metal component was the firing pin. The plans of this specific 3D printed gun were then later released amid a lot of public scrutiny and were downloaded 100,000 times within two days.

Whereas the United States government tried to stop the download and spread of these plans, it was impossible to undo the online release of this material.

Realistically, any firearm made almost entirely of plastic will have limited efficacy, and the effort required to make it functional is beyond the abilities of most home 3D printer owners.

Despite media speculation, since the initial story broke, there has not been a significant growth in homemade firearms due to 3D printing.

Drugs Printing

3D printing technology is also being welcomed in the pharmaceutical sector, with a US-based company going ahead and printing the first-ever 3D printed drug. The drug known as Spritam is used to treat seizures in patients who have epilepsy, and the technology for this drug was developed at MIT with the company trademark ZIpDose technology.

This 3D printed drug was produced by sandwiching the drug’s powdered form in between liquid materials and then bonding it at a microscopic level.

The development of 3D printed drugs is a massive leap towards the creation of customized medicine. Thus, changing the surface area of the tablet through 3D printing allows the appearance, rate of delivery, and size to be personalized depending on the person’s preference.

This innovation means that there might be on-demand drug-printing facilities at pharmacies, hospitals, clinics, or the patient’s homes in the future.

3D Printing Replacement Body Parts

The medical field has also embraced 3D printing technology, and this has led to several developments over the last few years in the bio-printing space. It involves research into how to use this technology for kidney transplants, limb replacement, heart transplant, as well as tissue repair and reconstruction.

There have been successful inventions in 3D printing the kidney and liver tissues, which could then be used in the treatment of human organs that are failing. Therefore, the use of this technology would see the saving of many lives in the future.

3D Printed Artworks for Blind People

3D printing technology is revolutionizing everything in the world for the better, and this includes the lives of visually impaired individuals. This is through the use of 3D printers to make classic artwork and paintings that are then changed to become 3D printed statues. Once in 3D printed form, the blind can then feel and appreciate amazing works of art in new and exciting ways that were not possible in the past.

Manufacturing Bicycles

Making bicycles on a large-scale using 3D printing technology will be a challenging prospect because of numerous construction challenges. Additionally, the size and cost of a suitable 3D printed is also an obstacle that threatens to hinder this goal from being achieved.

However, despite all these troubles, some companies have been able to design 3D printable bicycle parts, which you can design at home. Other manufacturers have managed to make 3D printed titanium parts. This is good news if you are a cycling fan as it shows all hope is not lost, and the use of 3D printing technology in making bicycles is not a far-fetched idea.

Shoes

Owning a pair of 3D printed pair of shoes is undoubtedly an appealing idea that would be a massive hit to everyone. These shoes can be personalized to fit your feet. A 3D scan of your feet can be taken and used to shape the 3D printed shoes to your exact shape.

A few big companies, including Under Armour, Adidas, and New Balance, have already released high-performance 3D printed shoes. The design of these shoes features a 3D printed upper part as well as 3D printed midsole, which offers a precision fit.

The use of 3D printing technology is also being embraced by other than making sporting shoes, and this is in making highly inventive shoes. Some of these 3D printed shoes are designed right before your eyes, and other concepts design 3D printed shoes using pictures of your feet.

It seems likely that in the near future, some shoe stores will have their own 3D printers and scanners so you can visit your local branch and order bespoke shoes!

Toys and Puzzles

You can easily use 3D printing technology to design something unique and entertaining, which your kids would love playing with. Therefore, you not only get to enjoy the entire 3D printing process, but also the created object.

Some of the popular 3D models you can create include puzzles of different shapes, fidget toys, building toys, and physics games.

The use of 3D printers to make toys and puzzles is quite widespread, overshadowing the technology’s advancements in other areas. Designing these objects is an excellent way to perfect your 3D printing skills.

Fabric

The clothing and fashion industries have also been quick to incorporate 3D printing technology. With this technological advancement, it is now easier to make designs that are unique and very appealing.

Nowadays, the use of this technology has become standard in the making of various substances, with the essential items being a 3D model and a model. Using 3D printers, you can make a basic lattice, chains, as well as other fabrics such as chainmail, which is a dynamic, expandable, and flexible fabric.

This fabric is almost identical to the regular material apart from the fact it requires neither weaving nor stitching. Consequently, you can use the 3D printed chainmail in your home on anything you wish.

As time passes, further innovations in 3D printing technology will make it possible to create more materials and substances. If these advancements could then reach a microscopic level, then medical and scientific industries can be in a position to better today’s world. Subsequently, this will see the development of new cures and treatments as well as improved accessibility to advanced technology.

Prosthetics

The making of prosthetics is one way through which the popularity of 3D printing technology has become widespread across the globe. Thanks to 3D printers, you can now design high-quality personalized prosthetics, which are very affordable. This is especially an appealing thing because 3D printed prosthetics are usually expensive to make in comparison to traditional-made prosthetics.

Conclusion

As you can see, the applications of 3D printing are limitless! There are examples of 3D printing being used in almost all aspects of our lives and this is only set to grow as more and more people see the advantages of using 3D printing.

Therefore, using 3D printing technology, you can design any object regardless of the desired shape. Furthermore, this technology’s availability and price further improve its appeal if you are looking for a perfect alternative way of making prosthetics.

Dylan