This page may contain affiliate links. As an Amazon Associate I earn from qualifying purchases.

FlashForge Creator Pro Sets A New High Standard For A Workhorse 3D Printer

FlashForge Creator Pro

Summary

The FlashForge Creator Pro is not only a solid workhorse of a 3D printer that can churn out print after print.

It also gives you the freedom to experiment with all aspects of FFF printing.

From material choice to Software you have all the options at your disposal.

One of the very best 3D Printers available.

The Creator Pro is a major upgrade to the popular Creator model. Most parts of the original Creator have been replaced or improved. This has resulted in a much higher quality 3D printer that looks poised to become the workhorse 3D printer to have.

What Does It Offer?

The Creator Pro is a Dual Extruder FFF 3D Printer. It has a heated build plate and enclosed design which means you can use it to print almost all exotic material filaments such as ABS, Nylon, Polycarbonate and various blend fills such as Bronze or Wood.

Because of its dual extruder capabilities, you can also print using dissolvable filament support structures. This opens up a whole world of more complicated design possibilities to you including printing moving parts and intricate woven designs.

What’s New?

Chassis

The most noticeable upgrade is the main chassis is now a very sturdy and professional looking steel construction where previously it was wood. This adds stiffness to the printer chassis which will greatly improve the accuracy and precision of the moving platform. The Z-axis guide rods are also upgraded to 10mm steel and will provide much more precise Z-axis control. Combined with reduced vibration you’ll see much more accurate and more reliable 3D printing.

The Z-axis guide rods are also upgraded to 10mm steel and will provide much more precise Z-axis control. Combined with reduced vibration you’ll see much more accurate and more reliable 3D printing.

Combined with reduced vibration you’ll see much more accurate and more reliable 3D printing with these upgrades.

Build Plate

The heated build plate has been upgraded to a hefty 1/4″ (6.3mm) aerospace grade aluminum. Such a thick plate is resistant to deformation even after repeated heating and cooling cycles.

As it retains heat better it is less susceptible to temperature fluctuations, providing a more stable platform for your print.

It can also withstand the high temperatures needed to print exotic filament materials such as polycarbonate (PC) or polypropylene (PP).

Enclosure

To give your prints the best environment for building the Creator Pro has a fully enclosed build chamber. This protects your prints from any external temperature or humidity changes in the room. A stable temperature is essential for printing the trickier materials like ABS which can easily deform if subjected to slight draught.

Ventilation is also improved which helps PLA filament to cool quickly after being extruded. You’ll achieve smoother profiles more accurate prints as the cooling fans cause the PLA to set the instant it is deposited before it has a chance to deform.

All this is achieved with a one piece acrylic cover rather than separately attached panels. This avoids bulky fixings that would otherwise take up the valuable volume in the enclosure.

You also get to open almost the whole front of the printer to access the build plate. This makes removing your finished print much easier than having to squeeze through a small window.

Setup and Unboxing

Compared to the well-designed packaging you get with printers like the Dremel 3D40, the Creator Pro unboxing experience was a little confusing. Firstly, you’ll find a lot of separately wrapped objects in the package. Secondly, the instructions are not very clear. They do the job but you’ll find yourself reading each sentence a few times to make sure you’re doing the right thing. The individual boxes aren’t labeled so it’s all a bit of a mystery as you unwrap each item what’s going to pop out.

The first task, if you’re in the USA, is to set the power supply voltage to 110V. This involves upending the printer and undoing a cover with a hex key to access the switch. It’s not a major issue but you will find it a little awkward to get to. And it’s a major hint that this is a 3D printer aimed at people who are willing to tinker rather than the average home consumer.

Thankfully it doesn’t get any more complicated than that. The next step is to attach the extruders to the gantry with a couple of screws, easy enough. Then the top acrylic cover and front door can be bolted on with a handful of screws each.

Attaching the two spools of filament is a simple process of threading the filament through the guides.

And finally, the build plate has to be leveled. This is a quick process as you only need to adjust three mounting points rather than the usual three. You don’t tend to go around in circles readjusting as is the case with something like the Makerbot Replicator. The adjustment screws have nice big plastic grips that are easy to turn. 3o seconds later you should be level and ready to print!

Software

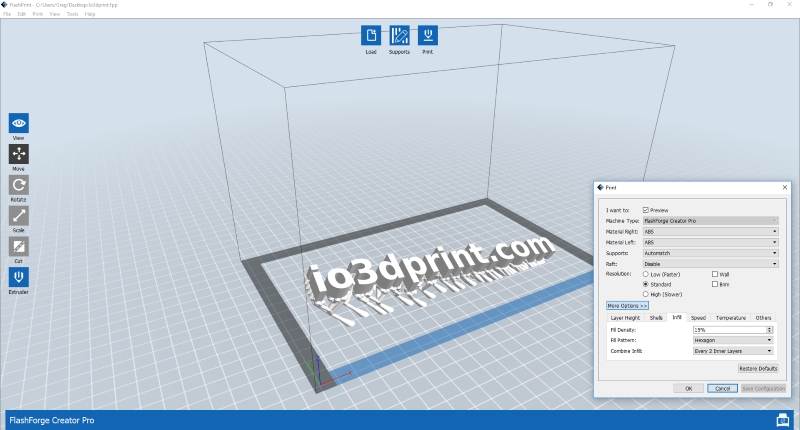

With the new 2016 model Creator Pro, you can now use FlashForge’s highly regarded FlashPrint Slicer software. Unfortunately, the manual still tells you to seek out the now long out of date ReplicatorG which is best avoided.

FlashPrint is very capable and will allow most people all the settings they need to change.

To get you started this has four standard profiles for PLA, ABS, Flexible, Conductive and HIPS (Dissolvable Filament). These will give you good results out of the box without you having to do any guesswork or research.

Once you’ve mastered a few basic prints, FlashPrint gives you the freedom to start changing various settings. Shells, infill types including triangle and hexagonal, infill density, print speed can all be altered to your requirements.

The Creator Pro has only one limitation in terms of software and that is it only prints X3G files rather than the standard G-code.

All this means is you have to transfer or export any G-code files you may want to use as X3G which isn’t a problem for the included Replicator and FlashPrint software or most other popular slicers such as Simplify3D.

Printing

Once you’ve exported your X3G file from FlashPrint or your chosen slicer software you must transfer the file to an SD-card to load it into the printer. This seems a bit out of date in the world of Wifi and clouds but ultimately isn’t too much of a burden, at least I don’t have to go hunting around for my Wifi password again…

The Creator Pro ships with a nice amount of 3M blue tape to help that all important first layer stick.

A few presses on the printer control panel and printing begins.

Noise level is quite low. This is definitely helped by the full enclosure and sturdy chassis. The motor noise can sound a bit frantic when using both extruders, but overall it’s about the same level as a normal office paper printer.

Some owners have found the door to rattle a little during printing. If yours does this you can just stick a little felt pad in the opening to prevent it.

Because of the quality heated build plate and enclosed design first layer sticking problems are rare with the Creator Pro. In general, you’ll find the print failure rate is close to zero with standard PLA or ABS material and settings.

The layer definition and general print quality on the minimum 100-micron layer height are very impressive.

You’ll be able to get good results straight away with default settings. But the power of the Creator Pro is its customizability.

As you experiment and start to push the boundaries you can play with temperatures, speeds, infills and supports with no limits. This enables you to get the absolute best from your materials, designs, and hardware.

Customer Service

One of the main benefits of being a Creator Pro owner is that you get to become a part of the fantastic community that’s built up around it.

Because it has become such a highly regarded workhorse 3D printer there is an endless supply of tutorials, tips, videos, upgrades and improvements available online.

And because FlashForge has made this an open source product there are no concerns about voiding warranties when you start to add upgrades. You can upgrade everything and anything on this printer to customize it exactly to your needs.

If you buy your Creator Pro from Amazon US then you will be able to tap into the legendary customer service of FlashForge’s Amazon US representative ‘Tang’ who has almost single-handedly given FlashForge their excellent reputation for customer satisfaction.

From careful guidance on how to unblock your extruder, to sending out straight replacements free of charge, FlashForge will look after you as a customer. A quick search through the Amazon reviews will show you how happy people are with the service they received.

Limitations

It’s not a major issue but depending on where you plan to site your printer you might find the main on/off switch is a bit awkward to get to.

The instructions that ship with the Creator Pro are not the best. They give you the basics but really don’t hint at just how much is possible with this printer. Your best bet is to get online to the community forums and youtube and work through some step by step tutorials.

The standard spool holder doesn’t fit many other types of filament. This is just a good excuse for you to print your own bespoke version! There are plenty of designs already available on Thingiverse.

FlashForge Creator Pro Verdict

You will get more from the Creator Pro than from any other 3D printer for the money. Add any single one of the many features to the fact that it is a genuinely reliable and dependable PLA printer and it should make it to your shopping list.

The fact is you can actually add a huge list of additional features including Dual Extrusion Printing, reliable ABS and exotic material printing, complete software freedom, complete material freedom and an infinite list of available upgrades and tweaks.

This should make the Creator Pro shoot to the top of your shopping list with little else to threaten it.

If you’re after reliable ABS printing the Creator Pro is hard to beat.

If you want the flexibility to try all material options and get to experience the fun of dual extruder 3D printing the Creator Pro is impossible to beat.

-Dylan

Last update on 2024-04-20 at 00:46